Milk & Processing Equipment

Playlist

0:16

0:16

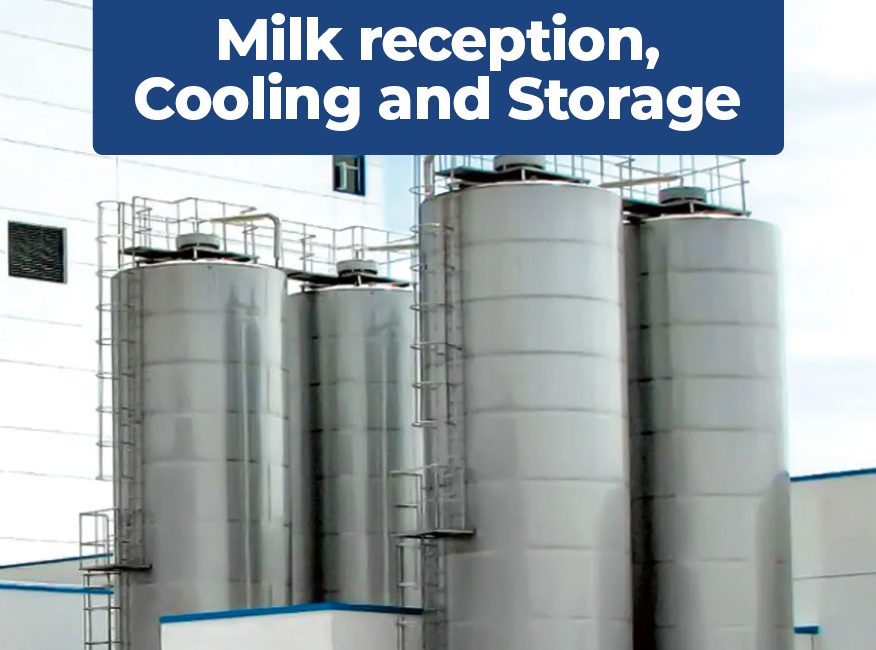

Milk reception, cooling and storage

The raw milk generally is transported by milk tank trucks, the raw milk should be kept under 14℃. After going through the reception and cooling line, the milk is cooled down to 4 ℃ and then be kept at this temperature at storage tank

Pasteurization and Cream Separator System

The milk pasteurizer is a device for the initial sterilization of raw milk, which can keep the raw milk at a low bacterial level. The cream separation standardization system is to bring the fat of milk to a certain level. It is composed of a centrifugal separator, a fat standardization system, and a storage tank for extra cream. To reduce steam and energy consumption, the plate heat exchanger is designed to have about 90% heat exchange efficiency.

Mixing System and Dissolving System

The blending system consists of a series of mixing tanks, heating and cooling systems, vacuum mixers or shear mixer, etc. It is used for dissolving and mixing ingredients such as sugar, milk powder and stabilizer. It can be used for producing all kinds of flavor milk, milk drink, fermented yogurt and etc.

Pasteurization /Sterilization and Homogenization System

The sterilization and homogenization system is used for sterilizing the final product, prolonging the shelf life of the finished product, and microparticle the fat of the milk to prevent the fat from floating up.

CIP Cleaning System

STB CIP system is designed to meet the specific requirements of the customer’s equipment and its associated utilities. The properly designed CIP system ensures complete removal of residue and efficient rinsing with proper flow and pressure, while saving cleaning time, operating costs and ensuring workers’ safety.

Visit Our Categories

Our mission is to empower farmers and livestock producers with the tools and technology they need to enhance the welfare and productivity of their livestock

Contact

Jl. Industri Cimareme 1, Kawasan Parahyangan Eco Business Park, Blok L1 No. 5 Padalarang Bandung Barat – Jawa Barat, 40553